Construction and Design Process

The journey of designing the rocket and CANSAT was marked by various challenges and numerous adjustments to meet our goals. Below, we detail the key phases of the construction process and the design changes implemented to enhance performance.

Back to Home

Initial Design

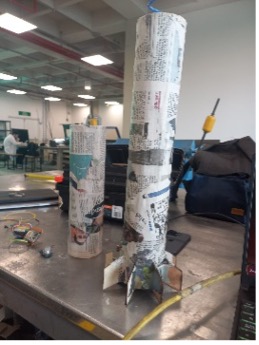

Our initial rocket design used a bullet-shaped nose cone for its aerodynamic properties, aiming to reduce air resistance during flight. However, challenges arose due to its weight, leading to a redesign using lighter materials while preserving structural integrity.

Final Design

The final rocket design included rectangular fins for better aerodynamic stability and durability. The structure was reinforced with lightweight stringers and frames, ensuring resistance to dynamic forces during flight.

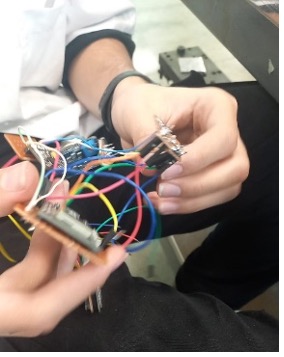

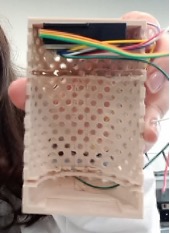

CANSAT Structure

The CANSAT featured a cylindrical design with hexagonal perforations, allowing airflow for environmental measurements. Internal "nails" were used to securely hold the circuit plates, ensuring stability during deployment.

Threaded Assembly

To securely join the two parts of the CANSAT, a 3D-printed thread was used. This design ensured a firm attachment while maintaining ease of assembly and disassembly.

Adjustments and Improvements

Several adjustments were made throughout the project to optimize performance:

- Fins: Redesigned from semi-triangular to rectangular shapes for better stability.

- Nose Cone: Changed materials to balance weight and maintain aerodynamics.

- Recovery System: Enhanced parachute deployment system to ensure safe landing of the rocket and CANSAT.

Creation Process Gallery